To deliver zero-defect precision components with on-time, cost-efficient production, while fostering strong partnerships, advancing technology and skills, and promoting sustainable manufacturing practices.

To redefine global standards in forging and precision machining through innovation, uncompromising quality, and sustainable growth — empowering industries worldwide with engineering excellence.

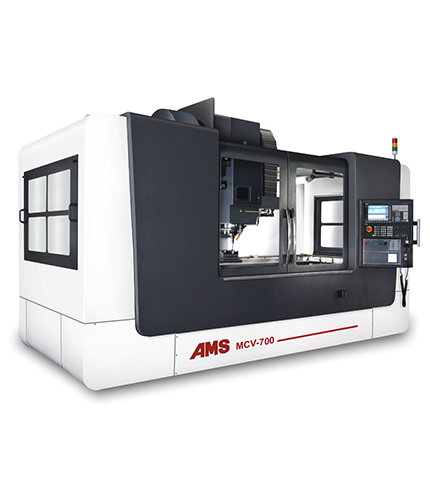

At BDS Manufacturing, we combine advanced engineering tools with deep domain expertise to ensure a first-time-right approach from design to production. Our in-house capabilities enable us to develop, simulate, and validate every component with precision — minimizing development cycles, optimizing material use, and ensuring consistent quality at scale.

Enhancing performance while reducing cost through smart design optimization.

Ensuring performance, strength, and durability under real-world conditions.

Designing lighter, stronger, and more manufacturable components for enhanced efficiency.

Developing robust, production-ready tooling solutions for consistent quality output.

Through this integrated engineering ecosystem, BDS ensures every project achieves excellence — in design precision, manufacturability, and long-term performance.