Welcome to BDS, a leading industry innovator with a rich history of excellence

BDS Manufacturing stands at the forefront of precision engineering, combining state-of-the-art forging and machining technologies to produce critical automotive components in steel, aluminium, titanium, and copper-based alloys. With a focus on innovation, reliability, and global standards of excellence, we deliver products that define performance across the automotive industry.

To deliver zero-defect precision components with on-time, cost-efficient production, while fostering strong partnerships, advancing technology and skills, and promoting sustainable manufacturing practices.

To redefine global standards in forging and precision machining through innovation, uncompromising quality, and sustainable growth — empowering industries worldwide with engineering excellence.

BDS Manufacturing stands at the forefront of precision engineering, combining state-of-the-art forging and machining technologies to produce critical automotive components in steel, aluminium, titanium, and copper-based alloys. With a focus on innovation, reliability, and global standards of excellence, we deliver products that define performance across the automotive industry.

To deliver zero-defect precision components with on-time, cost-efficient production, while fostering strong partnerships, advancing technology and skills, and promoting sustainable manufacturing practices.

To redefine global standards in forging and precision machining through innovation, uncompromising quality, and sustainable growth — empowering industries worldwide with engineering excellence.

At the heart of our manufacturing excellence lies a process built on precision, quality, and performance. Here’s how we transform raw materials into world-class automotive components:

Collaborate with clients to design precise, high-performance components using advanced CAD modeling and simulation tools.

Choose and forge premium steel, aluminum, or alloys to ensure superior strength, accuracy, and structural integrity.

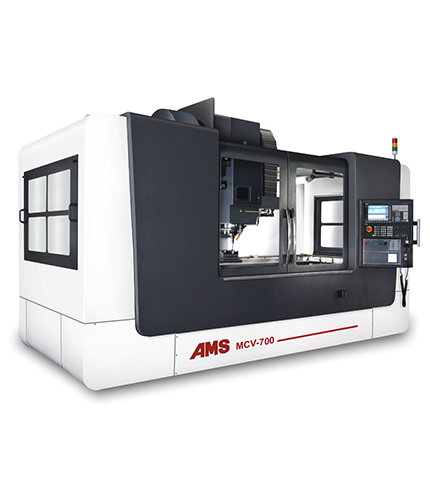

Perform precision CNC machining and heat treatment for tight tolerances, durability, and exceptional surface finish.

Conduct rigorous inspections using advanced metrology to guarantee zero defects and timely global delivery.

Let’s Build Precision Together – Reach out for inquiries, quotes, or collaboration opportunities.